The flow behaviour is fundamental for the efficiency of a system. We radically reduced the space requirement which means more filter performance in the same space, with less energy consumption.

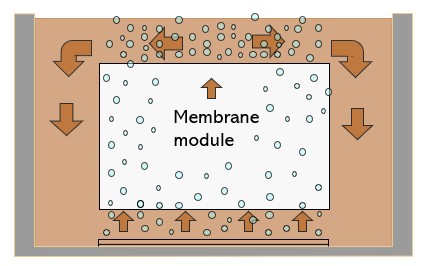

Even when individual elements are connected together, their boundary conditions must be taken into account. BundleTube ensures that internal and external flow conditions are the same for each membrane element. By creating defined downward flow zones within the module, the total installation space required for the modules is significantly reduced.

In all submerged membrane modules for MBR applications, air is introduced into the modules from below for flushing purposes. This creates an upward flow of sludge.

Downward flow zones between the membrane elements through BundleTube

Weitere Informationen gewünscht? – kontaktieren Sie uns…

© 2022 Membion GmbH